The Vital Applications of Titanium Alloy TC4 in Medical Devices

Introduction:

The field of medical devices is constantly advancing to improve treatment efficacy, reduce trauma, and extend patient lifespans. Within this ever-evolving landscape, materials science plays a pivotal role. Titanium alloy TC4, owing to its unique properties and numerous advantages, has gradually emerged as the material of choice in the manufacturing of medical devices. This article will delve into the crucial applications of TC4 titanium alloy in the realm of medical devices.

1. Corrosion Resistance:

TC4 titanium alloy boasts exceptional corrosion resistance, making it an ideal choice for the fabrication of implantable medical devices. For instance, medical implants such as artificial joints, dental implants, and cardiac stents, which require prolonged contact with bodily fluids and oxidative environments, benefit from TC4’s corrosion resistance.

2. Biocompatibility:

TC4 titanium alloy exhibits excellent biocompatibility with human tissues, implying that it does not trigger significant immune responses or rejection reactions. This is paramount for implantable medical devices as they need to interact with a patient’s tissues over extended periods without adverse reactions.

3. High Strength and Lightweight:

The high strength and relative lightweight nature of TC4 titanium alloy make it an ideal material for manufacturing medical devices subjected to high loads and stresses. Surgical instruments, bone plates, and screws, for example, which require strength and rigidity, can be fabricated using TC4 titanium alloy to ensure they do not deform or fracture during use.

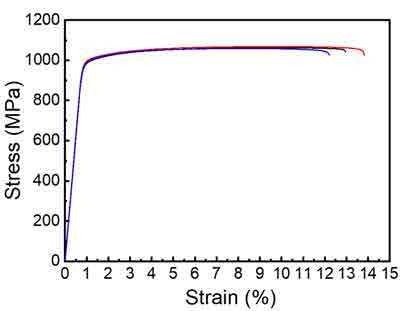

Performance:

● Density:≥99%

● Hardness:350-400 HV1

● Yield Strength:≥950 MPa

● Tensile Strength:≥1000 Mpa

● Modulus of elasticity:100-120GPa

● Elongation:10%-26%

4. Wear Resistance:

In certain medical device applications, wear resistance is a critical factor. TC4 titanium alloy is highly favored for its outstanding wear resistance. For instance, artificial heart valves and orthopedic implants that endure prolonged wear can benefit from TC4 titanium alloy, which extends their operational lifespan.

5. Customizability:

TC4 titanium alloy is easy to process and manufacture, allowing for customization to meet the specific needs of medical devices. Its malleability and machinability enable designers to create precision instruments tailored to patient requirements.

By adjusting the microstructure of MIMI-TC4 with a special process, the equiaxed microstructure similar to that of forged titanium alloy was obtained, with fine grains and greatly improved mechanical properties.

● Density is greater than 99%

● Yield strength greater than 900 mpa

● Tensile strength is greater than 1000 mpa

● Elongation is more than 10%

● Using low cost of powder to reduce the overall cost of the parts

Conclusion:

In conclusion, the significant applications of TC4 titanium alloy in medical device manufacturing cannot be understated. Its outstanding corrosion resistance, biocompatibility, high strength, lightweight nature, wear resistance, and customizability make it the preferred material for numerous medical devices. As medical technology continues to advance, we can anticipate broader applications of TC4 titanium alloy in the medical device field, providing patients with safer, more reliable, and effective treatment options.