On-demand manufacturing of Optical device components and rapid design

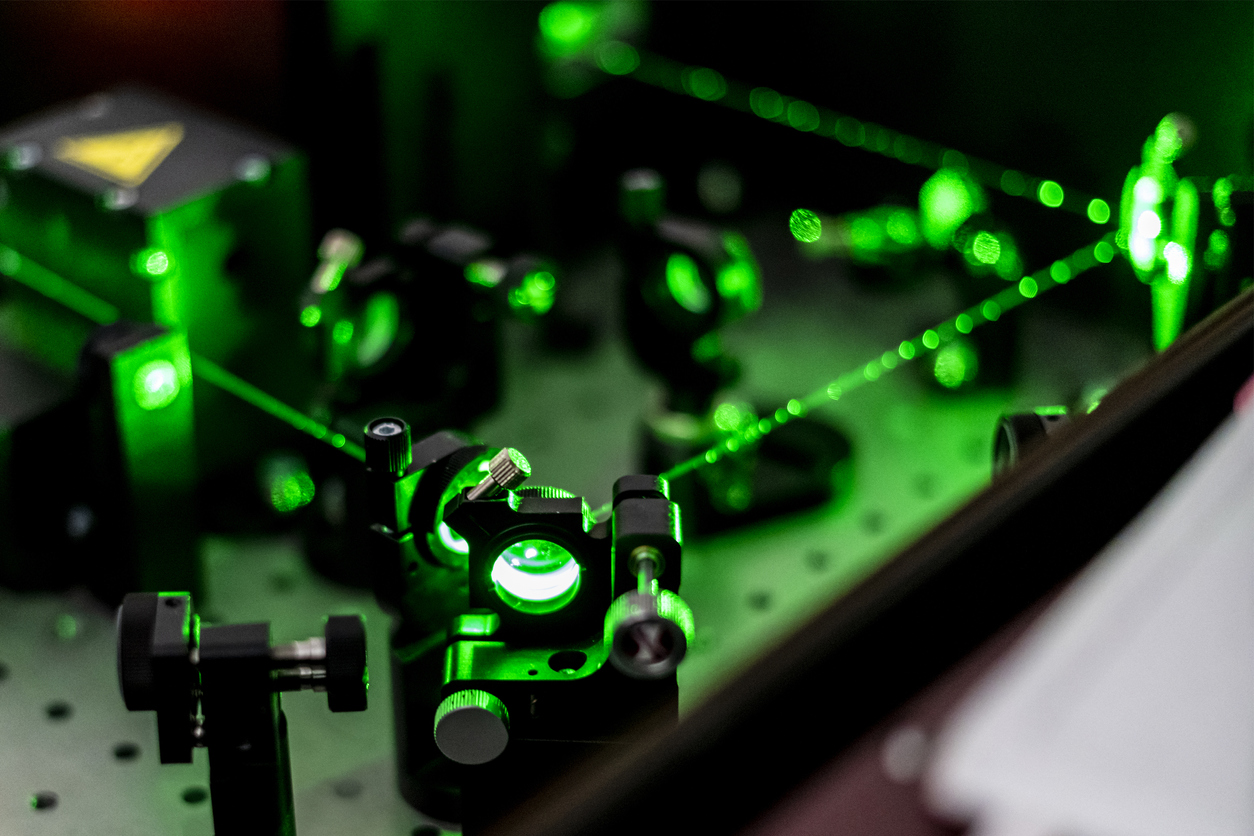

Optical Device Industry

XY-Global specializes in CNC Optical On-Demand Production for the Optical DeviceIndustry, providing competitive pricing and expertise in optical parts manufacturingOur commitment to excellence ensures reliable and cost-effective production ofcritical components.

-

High precision optical products

-

ISO 13485:2016 certified

-

24/7 engineering support

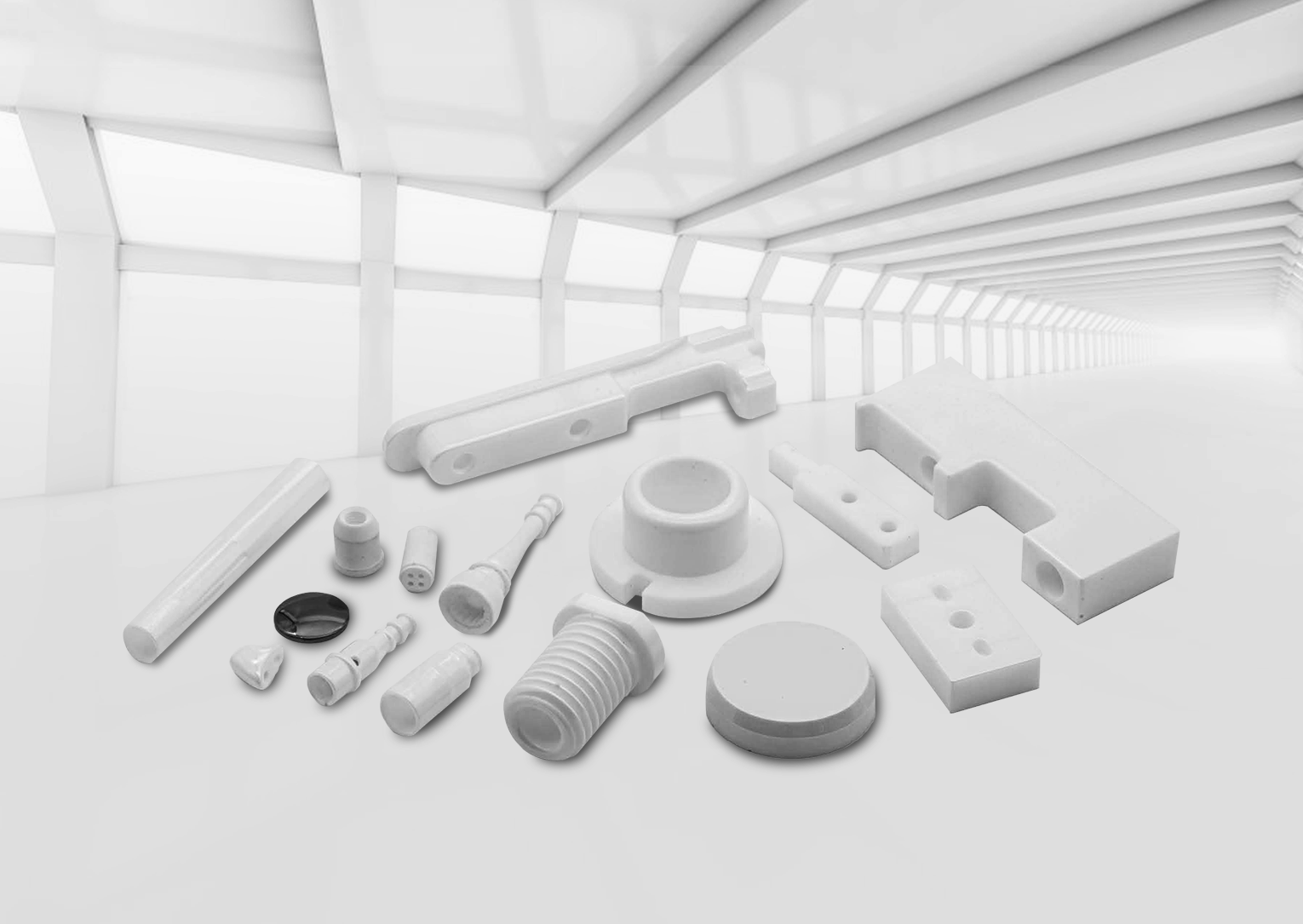

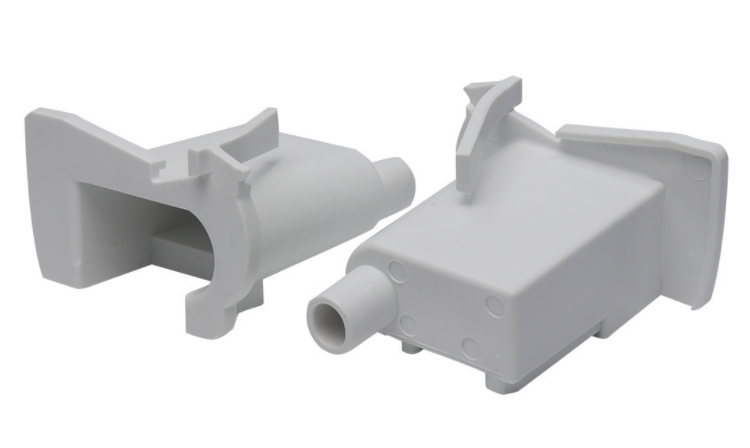

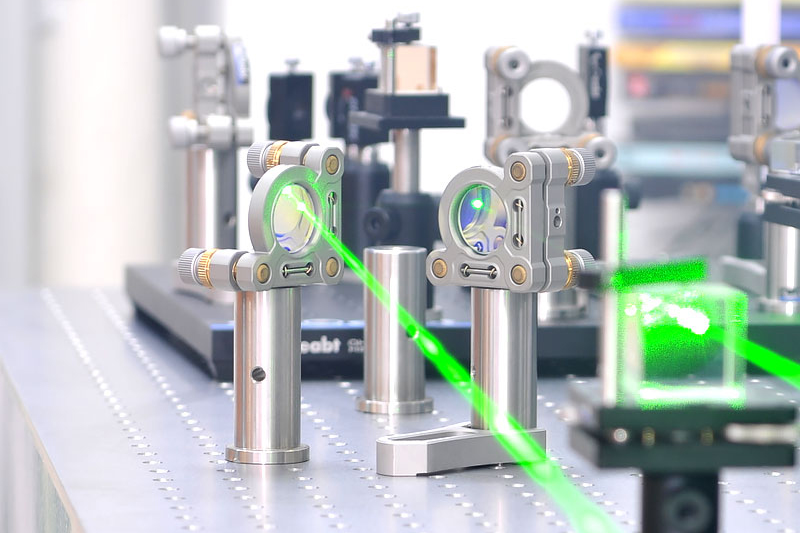

Custom Prototypes and Parts for Optical Devices Industry

Some of the leading companies in the optical industry trust our exceptional prototyping and manufacturing solutions for customizing their optical components. Our manufacturing capabilities and quality management systems guarantee that the parts we produce adhere to performance and safety standards.

Optical Applications

Our extensive production capabilities enable us to enhance optical device production to meet various industry applications. Some of these applications include:

-

Laser Scanner Accessories

-

Optical Extras Cover

-

Adjustment Screw

-

Optical Cover

-

Lens Barrel

-

Optical Bracket

-

Optical Lampshade

-

Laser Scanner Accessories

-

Optical Mount

Why XY-Global for Optical Industry

XY-global is at the forefront of delivering dependable optical prototyping, CNC machining, and production services customized to meet various complexities in optical components. With our integration of cutting-edge technologies and deep manufacturing expertise, particularly in optical device CNC machining, we are adept at bringing your optical innovations to fruition efficiently. Whether your components are intricate or straightforward, we possess the capability to assist you in achieving your goals through rapid prototyping and low-volume production, ensuring the success of your optical product.

Strong Capabilities

XY-GLOBAL is an ISO 13485:2016 and ISO 9001:2015 certified company. This shows we have excellent manufacturing capabilities, proper material certifications, and use advanced technologies. All Optical device parts from XY-GLOBAL meet regulatory compliance fully in dimensions, performance, strength, and more.

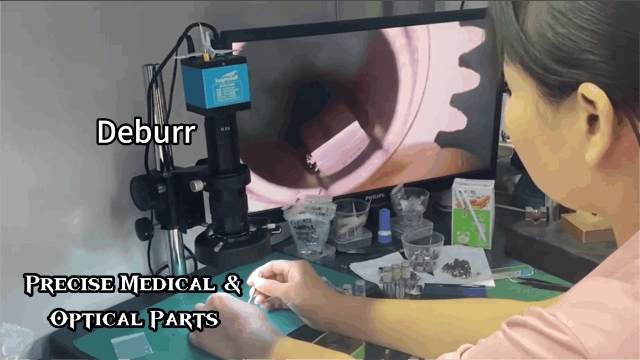

Precision Parts

Our optical part prototyping services provide parts that meet tolerance and accuracy requirements. We can manufacture optical parts to tolerances of +/-0.001 inches. Our machining technology and expertise also help us ensure the accuracy of your optical instrument prototypes.

Fully Customizable

XY-GLOBAL can expedite the production of optical components through our expertise in tailored design and specialized tooling. We collaborate closely with you to assess the distinctiveness of your products and employ advanced manufacturing techniques to transform your concepts into reality.

Instant Quotation

We improve the optical parts manufacturing experience with instant quotes that are constantly learning. Upload your design files and get feedback on DFM analyses, pricing and lead times in a short period of time. You can also control your orders with efficient tracking and management.

Fast Lead Time

Leveraging instant quoting and fast prototyping technologies, XY-GLOBAL can reduce customer lead times by over 50%. Our rich technical expertise and capabilities make this extreme efficiency possible.

We Are ISO 9001 Certified!

XY-global, a trusted supplier of optical device components, holds ISO 9001 certification, the standard for optical device manufacturing management systems. This recognizes that all optical equipment prototypes and components you receive from us meet comprehensive regulatory requirements. It also emphasizes our strong quality control and assurance system, assuring you that the parts we produce will meet your specific needs. We are ready to serve every customer!

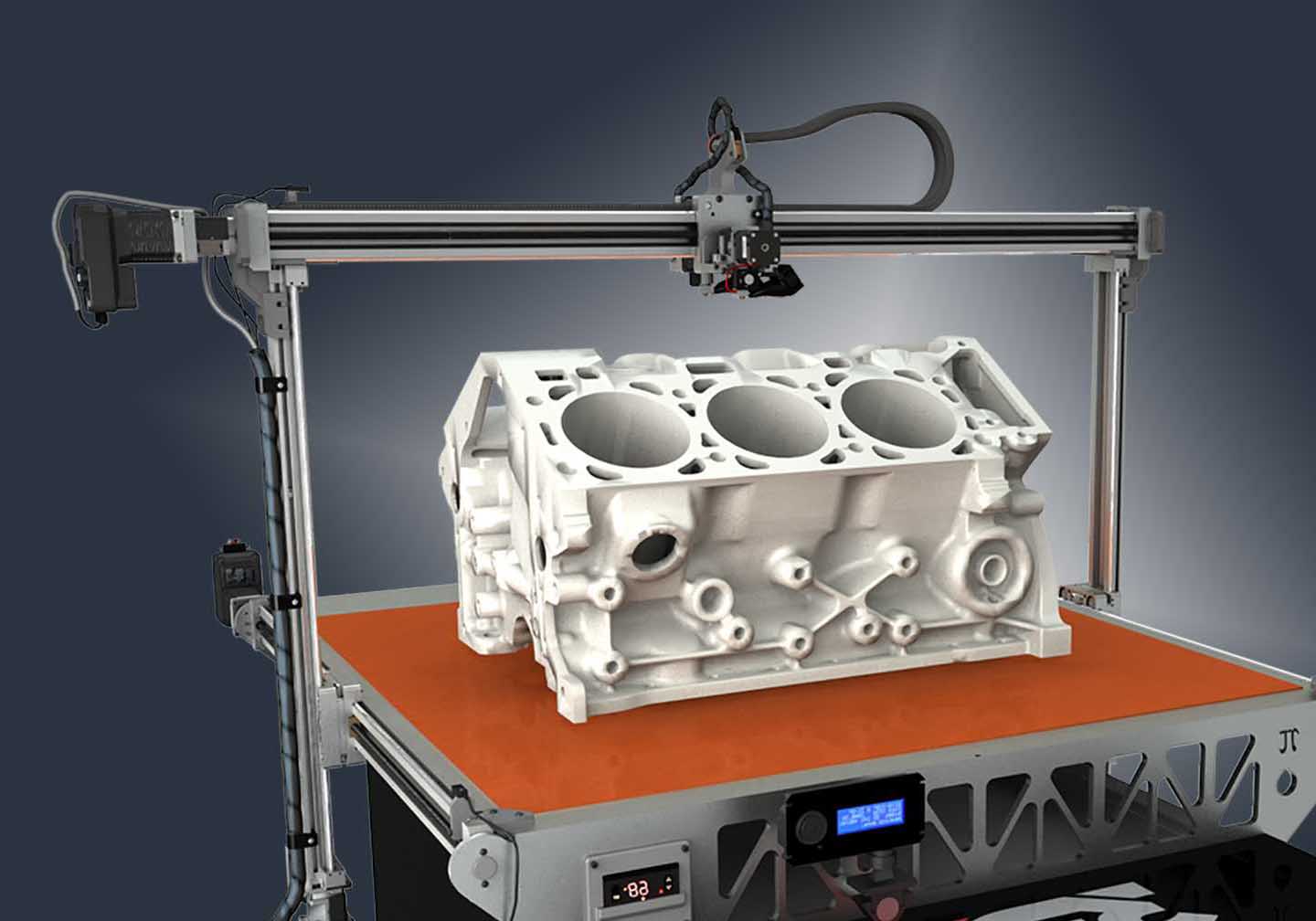

Prototyping to Production Stages for Optical Industry

Develop optical components with top-notch solutions. xy-global offers professionally designed and engineered custom products with superior durability and functionality. We offer solutions in various stages to help you achieve your production goals.

-

Prototyping

-

Engineering Validation and Testing (EVT)

-

Design Validation and Testing (DVT)

-

Production Validation and Testing (PVT)

-

Mass Production (MP)

Prototyping

Create quality prototypes with production-grade material for early-stage development. Analyze your design and make the right design or material changes to prepare the Optical prototypes for testing.

Prototyping

Upon analyzing your design file, our technicians will create prototypes to meet your design requirements. Your application will determine the materials and processes we will use to develop your component to look like the final product. This way, you can assess the specifications and carry out functional testing.

Engineering Validation and Testing (EVT)

Make quick and easy changes to functional Optical device prototypes after engineering testing and validation of performance requirements.

EVT

We create functional prototypes similar to the final product. This way, you can easily identify design problems and rectify these issues. There may be a need for a number of changes to ensure performance requirements are met.

Design Validation and Testing (DVT)

Combine your Optical equipment parts with our expertise to validate product performance, functionality, and aesthetics effectively. We facilitate necessary design iterations to optimize production time and cost savings.

DVT

We offer top-notch designs for manufacturing feedback to help you analyze the performance and appearance of your Optical prototypes. With a wide range of

materials, finishes, and mechanical designs, we will create components with ideal end-use functionalities and finishes for market testing.

Production Validation and Testing (PVT)

Get your design ready for mass production using production-grade machining processes and an advanced quality management system.

PVT

Take control of your product design with feedback from the technical team. This way, you can assess the manufacturability and suitability of your product and make the final changes for more efficient production.

Mass Production (MP)

Migrate from product testing stages to the full-scale production of end-use Optical parts. Adopt precise quality requirements and excellent manufacturing capabilities for high-quality products.

MP

We take your Optical device production to the next level with our advanced manufacturing processes and engineering expertise. Our experts work to ensure

your products meet quality and performance requirements at low costs and faster lead times.

Optical Device Manufacturing

The optical industry relies on precision-manufactured products to facilitate various visual and optical applications. We provide assurance to the optical industry through our ISO 9001-certified services. Committed to delivering precision and high-quality optical components in compliance with regulations and quality standards, we align seamlessly with our role as a trusted supplier of optical components. We offer reliable, professional manufacturing solutions for optical devices, ensuring customized products meet the highest quality standards.

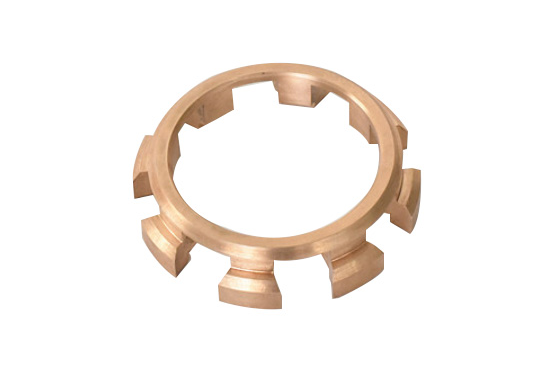

Right Materials for Optical Product Development

Our manufacturing techniques are compatible with a wide variety of materials to meet the demands of the optical industry. Our technicians possess ample experience and expertise in selecting the appropriate materials for optical product development, and we will collaborate with you to determine the material that aligns best with your requirements. Explore some of the most commonly used materials for developing optical device components.

- Stainless Steel

- Thermosets

- Ceramic Material

- Silicone Rubber

- Titanium

- Optical Plastics

Stainless Steel

Integrate this versatile low-carbon steel into your optical component manufacturing requirements. This non-toxic and non-corrosive material is available in various variants, catering to a diverse array of optical applications. While stainless steel is naturally durable, it can also be meticulously refined to optimize both its optical properties and aesthetic appeal, ensuring it aligns with the stringent standards of optical component fabrication.

Thermosets

Optical thermoset plastics maintain shape and integrity at high temperatures, ensuring precision in optical components.

Ceramic Material

Ceramic materials offer outstanding chemical stability, corrosion resistance, hardness, wear resistance, and biocompatibility, making them well-suited for specific optical applications.

Silicone Rubber

Silicone rubber, with its enhanced thermosetting properties, meets industry standards with its exceptional thermal stability and flexibility, facilitating easy sterilization using various methods. This material remains stable and flexible even under extreme optical conditions.

Titanium

Titanium alloy is particularly suitable for manufacturing the support frames of optical lenses in optical devices such as telescopes, microscopes, and cameras, ensuring the stability and precision of optical systems. Its high-temperature stability and corrosion resistance also make it an ideal choice for manufacturing components of laser systems and optical sensors, ensuring long-term stable operation and maintaining their performance and reliability.

Optical Plastics

Compared to glass, optical plastics are lightweight, impact-resistant and flexible in design, making them suitable for a wide range of optical applications. Compared to glass, it is cheaper and easier to process, and can meet the design needs of different products. Its excellent optical transparency and chemical stability also make it an ideal choice for many optical products.

Post-Processing for Optical Prototypes & Products

Explore XY-GLOBAL’s varied finishing options for optical prototypes and products, customized based on materials and applications

| Name | Description | Materials | Color | Texture | Link | |

|

Anodizing | Anodising can significantly improve the performance and appearance of optical components, making them more suitable for a variety of optical application scenarios. | luminum | Clear, black, grey, red, blue, and gold. | Smooth, matte | Learn More>> |

|

Powder Coating | The advantages of powder coatings for optical components are to provide abrasion resistance, corrosion resistance, excellent optical properties, color variety, and environmental safety. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | Learn More>> |

|

Electroplating | Electroplating is an aesthetic and functional finish that enhances the appearance, corrosion resistance, and mechanical properties of optical products, ensuring both visual appeal and durability. | Aluminum, Steel, Stainless Steel | n/a | Smooth, glossy | Learn More>> |

|

Bead blasting | Sandblasting improves the aesthetic appearance of optical equipment. It also reduces wear and tear on these parts, making them last longer. | Aluminum, Stainless Steel, Thermoplastics | Gray, black | Smooth, matte | Learn More>> |

|

Passivation | Passivation helps to remove particles from metal parts and prevent future corrosion. It creates adequate corrosion resistance to the product. | Stainless Steel, Aluminum, Titanium | Faint yellow, brown, straw | Smooth, matte, semi-gloss | Learn More>> |

|

Heat Treatment | Heat treatment helps to improve the corrosion resistance, strength and biocompatibility of the product. | Titanium, Aluminum, Stainless Steel | Faint yellow, brown, straw | Smooth, matte | Learn More>> |

Trusted by Fortune 500 Companies

-

Camera Equipment Manufacturer

-

Consumer Electronics Manufacturer

-

Communications technology companies

-

Technology startups

-

Optical System Integration Company

-

Optical Component Manufacturer

-

Optical Equipment Manufacturers

-

Optical engineering and design company

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Let's Start A New Project Today

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries. Click on the link below to know more.

Explore More Resources

Plastic injection molding companies can produce durable, high-strength, high-quality components. The process can be used for prototyping new designs and ... Read more

Although oxygen keeps humans and practically every other lifeform on Earth from going the way of the dinosaurs, it’s actually ... Read more