Semiconductor equipment support frame

OTHER configuration:

Material: SUS304/316

Process: turning-milling-polishing deburring

Annual volume: 400,000-600,000 PCS

Features: the material is not easy to cut, cross-hole burr is not easy to remove, high appearance requirements

Product Description

product size chart or static pressure:

Product Specfications

Introduction:

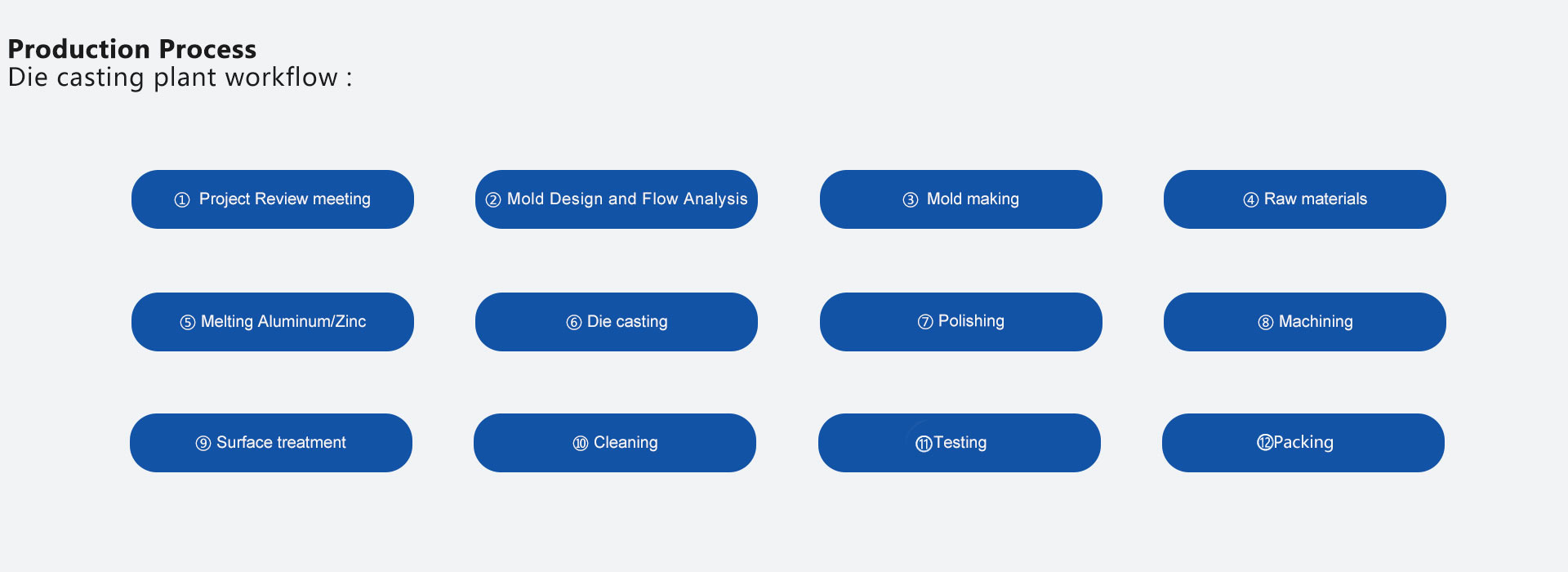

We specialize in providing customized semiconductor base frame components manufactured with high-quality aluminum alloys (ADC12, A380, A360) and zinc alloys (ZINC#3, ZINC#5). Our products are created using advanced die casting and CNC machining processes, ensuring exceptional performance and precise dimensions.

Product Highlights:

- Wide material selection: Aluminum alloys (ADC12, A380, A360) and zinc alloys (ZINC#3, ZINC#5).

- Fine craftsmanship: Utilizing advanced die casting and CNC machining processes.

- Diverse surface finishes: Options include powder coating, anodizing, painting, and chrome plating.

- High precision tolerance: Strict manufacturing processes guarantee tolerances within +/- 0.1mm.

Please find detailed information regarding the materials and processes used for our products below:

Note: Our products are known for their high precision and a wide range of surface finish options, allowing for customization based on specific customer requirements. We are dedicated to providing superior semiconductor base frame components. Please feel free to contact us for further details and custom solutions.

NO.

Material

Process

Surface Finish

1

Aluminum ADC12

Die Casting& CNC

Powder Coating,

Machining

Anodizing

2

Aluminum ADC12

Die Casting& CNC

Painting,

Machining

Anodizing

3

Aluminum A360

Die Casting& CNC

Chrome Plating

4

Zinc #3

Die Casting& CNC

Powder Coating

Machining

Painting

5

Zinc #5

Die Casting& CNC

Powder Coating

Machining

Anodizing

Introduction:

We specialize in providing customized semiconductor base frame components manufactured with high-quality aluminum alloys (ADC12, A380, A360) and zinc alloys (ZINC#3, ZINC#5). Our products are created using advanced die casting and CNC machining processes, ensuring exceptional performance and precise dimensions.

Product Highlights:

- Wide material selection: Aluminum alloys (ADC12, A380, A360) and zinc alloys (ZINC#3, ZINC#5).

- Fine craftsmanship: Utilizing advanced die casting and CNC machining processes.

- Diverse surface finishes: Options include powder coating, anodizing, painting, and chrome plating.

- High precision tolerance: Strict manufacturing processes guarantee tolerances within +/- 0.1mm.

Please find detailed information regarding the materials and processes used for our products below:

Note: Our products are known for their high precision and a wide range of surface finish options, allowing for customization based on specific customer requirements. We are dedicated to providing superior semiconductor base frame components. Please feel free to contact us for further details and custom solutions.

| NO. | Material | Process | Surface Finish |

| 1 | Aluminum ADC12 | Die Casting& CNC | Powder Coating, |

| Machining | Anodizing | ||

| 2 | Aluminum ADC12 | Die Casting& CNC | Painting, |

| Machining | Anodizing | ||

| 3 | Aluminum A360 | Die Casting& CNC | Chrome Plating |

| 4 | Zinc #3 | Die Casting& CNC | Powder Coating |

| Machining | Painting | ||

| 5 | Zinc #5 | Die Casting& CNC | Powder Coating |

| Machining |

Anodizing |