Process comparison of injection moulds, extrusion moulds and blow moulds

Plastic molds are tools used to produce plastic products and are divided into several types such as injection molds, extrusion molds and blow molding molds . Different types of molds are different in manufacturing process and usage method. In the following we will introduce the process characteristics of these types of plastic moulds respectively.

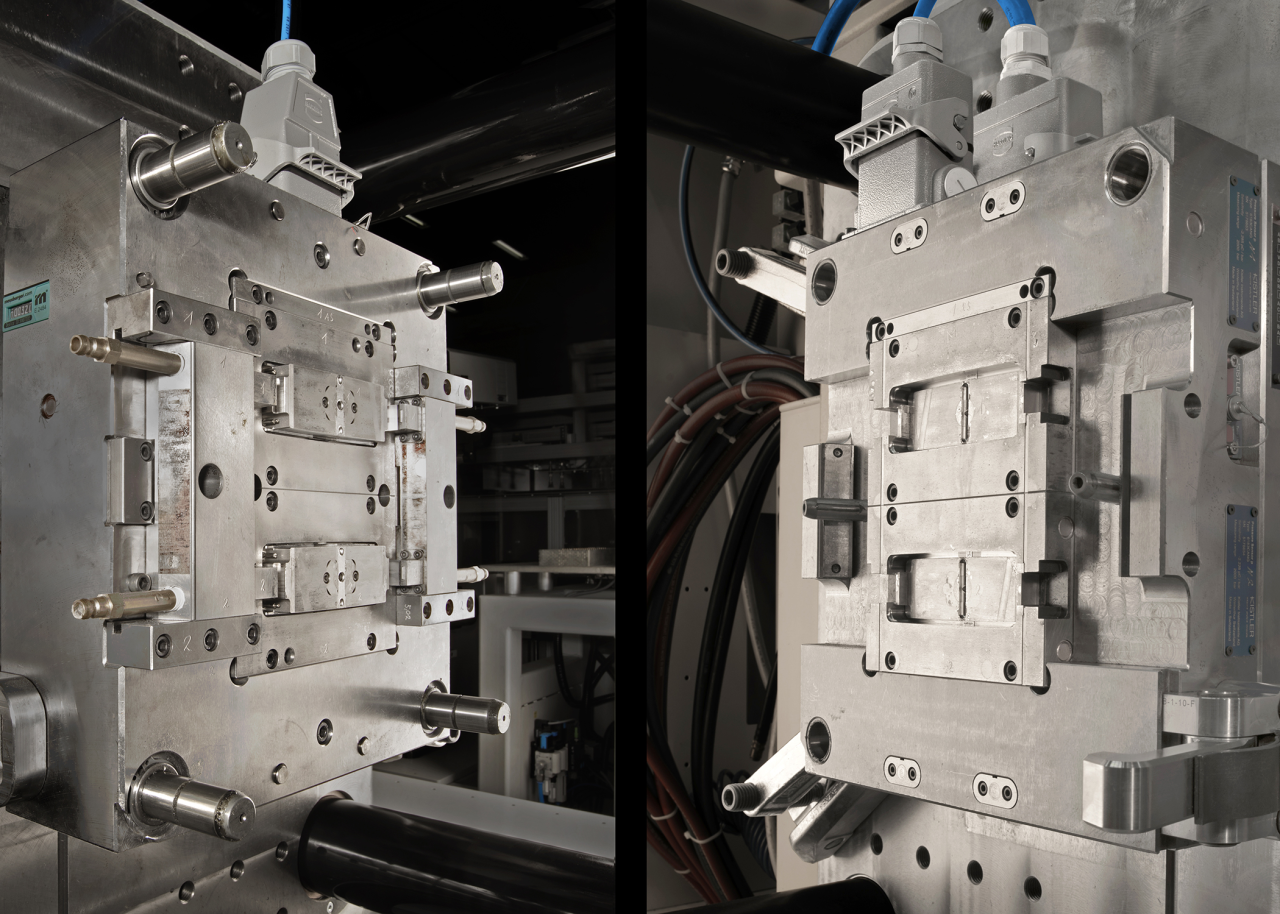

Injection Molds

Injection mold is a tool used to produce injection molded parts, which usually consists of mold base, mold cavity, ejector, ejector bar, bottom pin, bottom bar, guide pillar, guide bush and other components. Its manufacturing process generally includes the following steps:

(1) Mold design and drawing, design the mold structure and cavity shape according to the structure and requirements of the product.

(2) Processing mold base and cavity, using CNC machining center and other equipment for precision machining.

(3) Installing mold parts, including ejector pins, bottom pins, guide pillars, guide bushings, etc.

(4) Debugging the mold, adjusting the injection process parameters and testing the mold to ensure that the quality of the produced product meets the requirements.

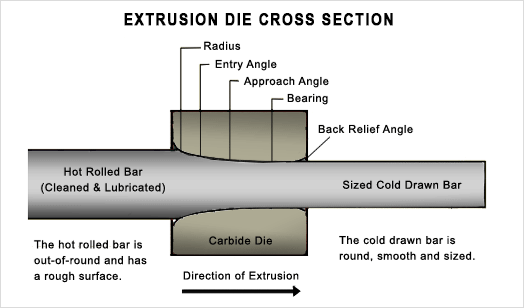

Extrusion die

Extrusion mold is a tool used to produce extruded plastic products, consisting of mold base, extrusion head, cavity and other components. Its manufacturing process generally includes the following steps:

(1) Mold design and drawing, design the mold structure and cavity shape according to the structure and requirements of the product.

(2) Machining the die base and cavity, using CNC machining center and other equipment for precision machining.

(3) Installing extrusion head and die parts, including guide pillar, guide bush, etc.

(4) Debug the die, adjust the extrusion process parameters and test the die to ensure the quality of the produced product meets the requirements.

Blow molding die

Blow molding mold is a tool used to produce blow molded plastic products, consisting of mold base, cavity, nozzle, guide pillar, guide bush and other components. Its manufacturing process generally includes the following steps:

(1) Mold design and drawing, design the mold structure and cavity shape according to the structure and requirements of the product.

(2) Processing mold base and cavity, using CNC machining center and other equipment for precision processing.

(3) Installing blowpipe and mold parts, including guide pillar, guide bush, etc.

(4) Debugging the mold for blow molding work