In-Depth Application of High-Precision Manufacturing in the Medical Field: CNC Technology Analysis

Why Choose CNC Machining to Develop Products in the Medical Industry?

CNC Machining for Medical Device Manufacturing is revolutionizing the medical industry by enabling ultra-precise, consistent, and customized production of complex components. From orthopedic implants to surgical tools, medical CNC machining ensures the tight tolerances and biocompatible finishes required in modern healthcare applications.

As the demand for personalized and minimally invasive treatment grows, manufacturers are turning to CNC technology to produce critical medical parts with unmatched precision. In this article, we’ll explore how CNC machining powers the next generation of medical device innovation — and what it means for both engineers and patients alike.

CNC processing technology plays a vital role in the manufacture of medical devices. CNC technology achieves high-precision processing of complex shapes and fine structures through numerical control equipment, ensuring the precision and functionality of medical parts and meeting the production requirements of medical device housings and components. These technologies not only improve the manufacturing accuracy and reliability of medical equipment, but also greatly improve production efficiency, providing strong support for further innovation in the medical device industry.

1. Demand for Precision Parts in the Medical Field

Breakthroughs in modern medicine are inseparable from the precision components that top surgeons and technicians depend on. These parts are critical in surgical instruments, implants, and diagnostic devices. As patient expectations rise and quality of life becomes a core outcome, the demand for medical CNC machining has never been higher. Devices must meet extremely tight tolerances to ensure safety, reliability, and long-term performance.

At XY-GLOBAL, we understand the unique challenges in CNC machining for medical device manufacturing. Whether you’re developing test prototypes or scaling up production for a new device line, our machining medical devices process ensures each part meets the highest standards of precision and consistency. We help customers bring high-quality medical equipment parts to market — accurately and efficiently.

Commitment to High Standards in Precision Medical Machining

XY-GLOBAL’s manufacturing facility adheres to some of the strictest standards in the industry when it comes to machining high-precision medical equipment parts, particularly for surgical instruments and implant components. Our CNC machining services are engineered to meet the rigorous demands of the medical field, where accuracy, cleanliness, and material integrity are paramount.

Precision manufacturing is not only our specialty — it’s the foundation of the trust we’ve built with medical device companies worldwide. Every part we deliver reflects our deep commitment to patients, surgeons, and the technicians who rely on these products to improve lives.

- In the manufacture of medical devices, biocompatibility, corrosion resistance and surface finish are crucial requirements. First, biocompatibility means that the device materials must be compatible with human tissues and fluids to avoid triggering immune responses or rejection reactions, which is especially important in the manufacture of implants. Secondly, corrosion resistance is extremely critical for medical devices, especially in environments where they are in long-term contact with body fluids or require frequent disinfection, such as surgical instruments and diagnostic equipment. The materials must be able to resist corrosion and maintain structural integrity. Finally, surface finish directly affects the use effect of the device. A smooth and flawless surface can not only improve the operating performance of the device, but also reduce the risk of bacterial growth, thereby improving the safety and durability of the device. These requirements have put forward higher standards for the material selection and processing technology of medical device parts.

Optimized Section 2: Application of CNC Technology in the Medical Field

The Role of CNC Machining in Medical Device Manufacturing

CNC machining for medical device manufacturing plays a foundational role in delivering the precision and complexity required by modern healthcare. With the ability to produce tight tolerances, complex geometries, and consistent results across production batches, medical CNC machining is indispensable in the fabrication of critical medical equipment parts.

Below are key application areas where CNC technology demonstrates its value:

1. Minimally Invasive Surgical Instruments

Medical CNC machining is widely used to manufacture minimally invasive surgical tools, which demand both compact form and intricate detail. Components such as micro-forceps and vascular or neurosurgical catheters rely on micron-level accuracy and burr-free surfaces to function effectively within delicate anatomical spaces. CNC precision ensures reliability, sterility, and structural integrity.

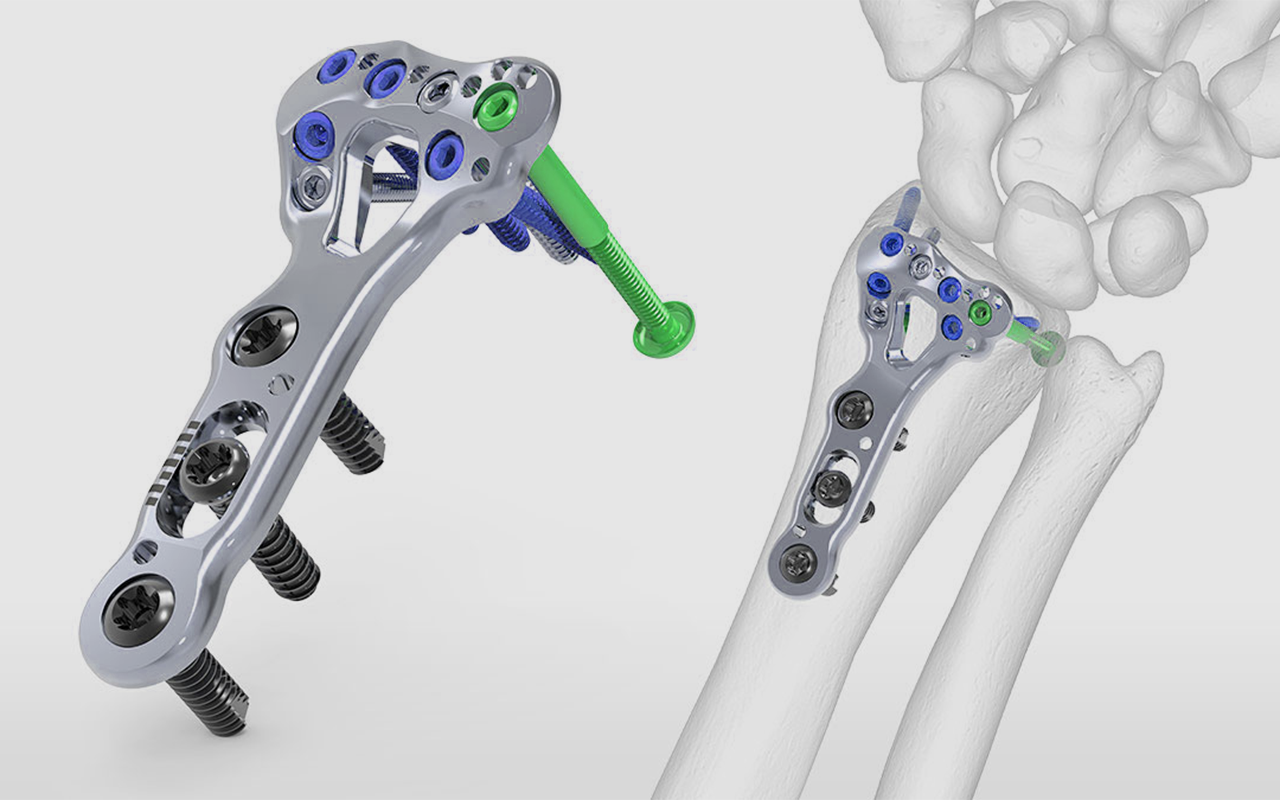

2. Implant Manufacturing

CNC machining is essential for the production of biocompatible implants such as hip and knee joints, spinal cages, and dental implants. These medical equipment parts must match patient anatomy with sub-millimeter accuracy. CNC allows the use of materials like titanium alloys and medical-grade stainless steel, while maintaining micron-level dimensional tolerances that ensure a secure fit and long-term functionality.

3. Customized Medical Devices

With the growth of personalized medicine, CNC machining for medical device manufacturing is increasingly used to produce custom medical devices such as braces, orthopedic supports, and rehabilitation aids. CNC allows rapid design iteration, short lead times, and efficient scaling — all critical for delivering tailored solutions that match individual patient needs.

Typical Use Cases

Below are representative products manufactured through precision CNC machining:

-

Lumbar Fusion Devices (PEEK): Featuring tooth-like surfaces for secure endplate fixation, anatomical curvature for lumbar support, and large grafting space.

-

Cervical Fusion Cages (PEEK): Designed to match cervical anatomy and preserve bone structure during implantation.

-

Cannulated Bone Screws: Manufactured with strict tolerances for orthopedic procedures, ensuring consistent thread depth and internal cannulation for guided screw placement.

- Hollow double-head compression screw

It adopts hollow double-start thread pressurized, countersunk, low-profile, self-tapping design.

- Hollow headless compression screw

Hollow design: improves the accuracy of percutaneous implantation.

Variable pitch thread and taper design: The pitch changes from large to small, and the head enters the bone faster than the tail, so that when the screw is screwed in, the fracture surface is pressurized.

Fully threaded design: better maintains pressurization function when subjected to periodic overloading.

Headless design: When used in the joint area, it reduces collision and irritation to soft tissue.

- How to improve precision control through CNC machining to ensure the safety and functionality of medical devices.

CNC machining technology plays a vital role in medical device manufacturing due to its high precision and automated control capabilities. The following are some key ways that CNC machining improves precision control through technical details to ensure the safety and functionality of medical devices:

①Multi- Axis Control and Precise Processing of Complex Geometric Structures

CNC machine tools are usually equipped with 3-axis, 4-axis or even 5-axis control functions, allowing multiple angles of the workpiece to be processed simultaneously. This multi-axis control technology can complete the processing of complex geometric structures in one clamping, reducing the errors of workpiece movement and re-clamping, thereby improving the dimensional accuracy and consistency of medical device parts.

②Micron-Level Tolerance Accuracy

In the manufacture of medical devices, tolerance requirements often reach the micron or even sub-micron level. CNC technology can ensure that the processing accuracy reaches a very high level and the error can be controlled within a very low range through precise CNC programs and closed-loop servo control systems. This is especially important for the production of products such as implants and surgical instruments that require extremely high precision.

③Automated Detection and Real-Time Feedback

CNC processing equipment is usually equipped with an online detection system, which monitors the processing status of the workpiece in real time through sensors and measuring equipment. This automated detection function can detect errors that may occur during the processing and adjust the processing parameters in time to ensure the processing accuracy of the product. At the same time, through the feedback control system, the CNC machine tool can automatically correct the deviation to ensure that the accuracy of the parts meets the design requirements.

④High Surface Finish Control

Medical devices have high requirements for surface finish, especially implants and minimally invasive surgical tools. CNC machining can produce parts with extremely smooth surfaces through high-speed cutting and fine tool selection, reducing the need for subsequent surface treatment. The improvement of finish not only enhances the functionality of the device, but also effectively reduces the risk of bacterial growth on the surface of the device, ensuring the safety of medical devices.

⑤Optimization of material selection and cutting parameters

For high-strength, biocompatible materials commonly used in the medical field (such as titanium alloys, stainless steel, etc.), CNC machining technology ensures high-precision cutting effects by optimizing cutting speed, feed speed and tool materials. Accurate parameter settings can effectively control material deformation and stress concentration, ensuring the functionality and long-term stability of parts.

Through these technical means, CNC machining in medical device manufacturing not only ensures the high precision of the product, but also improves safety and functionality, ensuring that the equipment can operate stably for a long time in the medical environment and meet strict quality and safety standards.

4. The Importance of Material Selection

Medical grade materials play a vital role in the manufacture of medical devices. These materials not only need to have high strength and durability, but also meet stringent biocompatibility and corrosion resistance requirements to ensure safe and long-term use in medical environments. The following are some commonly used medical grade materials and their characteristics and applications:

①Stainless steel

Stainless steel, especially 316L stainless steel, is one of the most widely used materials in medical devices. It has excellent corrosion resistance and can resist corrosion from human body fluids, disinfectants, etc. for a long time. In addition, it has good mechanical strength and processability, and can meet the precision and strength requirements of manufacturing surgical tools, surgical instruments and implants. Due to its strong biocompatibility, stainless steel is also widely used in the manufacture of bone screws, stents and surgical forceps.

②Titanium alloy

Titanium alloy has become one of the preferred materials for manufacturing medical implants due to its excellent biocompatibility and extremely high corrosion resistance. Titanium alloy has an elastic modulus similar to that of human bones, which reduces the stress shielding effect of implants in the body and promotes bone healing. This material is commonly used in hip and knee implants, dental implants, and heart stents. Titanium alloy is light in weight, high in strength, and has excellent fatigue resistance and can withstand long-term mechanical pressure.

③Magnesium alloy

Magnesium alloys are gradually gaining attention in the medical field due to their biodegradable properties. Unlike traditional implant materials, magnesium alloys can gradually decompose in the human body, avoiding the need for secondary surgery to remove them. This biodegradability makes them an ideal choice for fields such as orthopedic implants and vascular stents. At the same time, the mechanical properties of magnesium alloys are close to those of human bones, which can effectively promote the regeneration and repair of bone tissue. However, the corrosion rate of magnesium alloys needs to be carefully controlled to prevent them from degrading too quickly in the body.

④Aluminum alloy

Aluminum alloys are also commonly used in the manufacture of medical devices due to their light weight and excellent processing properties, especially in equipment that needs to be lightweight and portable, such as surgical light stands, wheelchairs, medical equipment frames, etc. Aluminum alloys have good corrosion resistance, and after surface treatment, such as anodizing, their durability and biocompatibility can be further enhanced. In addition, aluminum alloys have good thermal conductivity and are also suitable for some medical devices that require heat dissipation.

⑤Other materials

In addition to the above materials, medical grade plastics (such as PEEK, polyethylene, polypropylene, etc.) are also widely used in the manufacture of medical devices, especially some parts that require high flexibility, chemical resistance and insulation. Each material has its own unique properties and can meet the special needs of the medical industry for different functions and environments.

6. Future prospects: The prospects of CNC technology in the medical industry.

With the continuous advancement of technology, the application prospects of CNC processing in the medical industry are becoming increasingly broad. Here are a few major trends:

The integration of additive manufacturing and CNC machining

The combination of additive manufacturing (such as 3D printing) and CNC machining will significantly increase the design and manufacturing flexibility of medical devices. 3D printing is capable of creating complex shapes, while CNC machining is responsible for the fine machining and surface treatment in the later stages. For example, in the production of dental printing and custom implants, 3D printing generates the basic structure and CNC machining ensures precision and smoothness to meet medical-grade standards.

The Processing Capabilities of New Materials Have Improved.

With the development of biodegradable materials, high-performance alloys and biocompatible composite materials, CNC processing technology will continue to advance to meet the processing needs of these new materials. In the future, CNC machining will require higher precision and flexibility to maintain material properties, which will improve patients’ medical experience and expand the scope of medical device applications.

The widespread application of personalized medical devices

The demand for personalized medical devices will continue to grow, especially in the fields of braces, dental implants and orthopedic implants. Combining CNC machining, 3D scanning and additive manufacturing, manufacturers can quickly respond to personalized needs and produce customized medical devices, thereby providing more accurate treatment plans and improving patient satisfaction.

Through these technological advances, CNC machining will play a more important role in the medical industry, driving the entire industry towards a more accurate, efficient and intelligent direction.

7. Conclusion

- High Precision and Complex Design : CNC machining and die-casting technologies ensure high-precision manufacturing of medical devices, enabling complex geometries to meet the stringent requirements of surgical instruments, implants and diagnostic equipment.

- Personalized Medical Solutions : These two technologies support rapid response to patient needs and can produce customized medical devices such as orthotics and implants, improving the precision and effectiveness of treatment.

- Integration of new technologies and efficiency improvement : With the integration of new technologies such as additive manufacturing, CNC and die-casting technologies are driving the development of medical device manufacturing towards intelligence and flexibility, reducing production costs, shortening delivery cycles, while ensuring product safety and quality.

Note: Selecting high-precision machining technology is essential to ensure the quality of medical devices and patient safety. The manufacturing process of medical devices must follow strict standards and specifications to ensure their reliability and effectiveness in practical applications. High-precision machining technologies such as CNC machining can achieve micron-level precision control to ensure the consistency of size and shape of each part, thereby reducing potential failures and errors. In addition, CNC can process complex geometric structures, so that medical devices can achieve optimal functionality and adaptability, thereby improving treatment effects and patient safety. In the medical industry, any small mistake can lead to serious consequences. Therefore, the use of high-precision machining technology is the key to ensuring product quality and protecting patient safety.

As a premium supplier of precision CNC machining for medical applications, we invite you to visit our website to learn more about our services. We are committed to providing customized solutions that support the innovative manufacturing of high-precision medical devices and spare parts. We look forward to working with you to enhance the quality and safety of medical devices. Keep in touch with us to discuss your specific needs—together, we can drive progress in the medical industry!