How Well Do You Know About Different Types of Orthopedic Plates?

Medical Bone Plates It is an orthopedic instrument used in medical procedures and is commonly used for fracture repair and implant fixation. As an important medical device, the production of medical bone plates requires certain qualifications and technical conditions.

Materials are the key to the manufacturing of medical bone plates.

Medical bone plate materials need to have excellent biocompatibility and mechanical properties to ensure safety and effectiveness after surgery. Commonly used materials include titanium alloy, stainless steel, magnesium alloy, etc. Different materials have different characteristics and need to be selected for specific application needs: 1:

1. Titanium alloy: Titanium alloy is one of the most commonly used medical bone plate materials with high strength, excellent biocompatibility and histocompatibility, and can exist stably in the body for a long time. In addition, titanium alloys also have good corrosion resistance and excellent fatigue resistance, which can effectively resist the erosion and mechanical effects of the in vivo environment.

2. Stainless steel: stainless steel is another common medical bone plate material with high strength, excellent corrosion resistance and biocompatibility, which can exist in the body for a long time. Stainless steel bone plate is slightly inferior to titanium in terms of mechanical properties and biocompatibility, but its manufacturing cost is relatively low and is suitable for some areas with relatively poor economic conditions.

3. Biodegradable materials: Biodegradable materials can be gradually decomposed and absorbed in the body without the need for secondary surgery, so they are suitable for smaller fractures or bone fracture repair. Common biodegradable materials include polylactic acid, polyhydroxyacetic acid, etc.

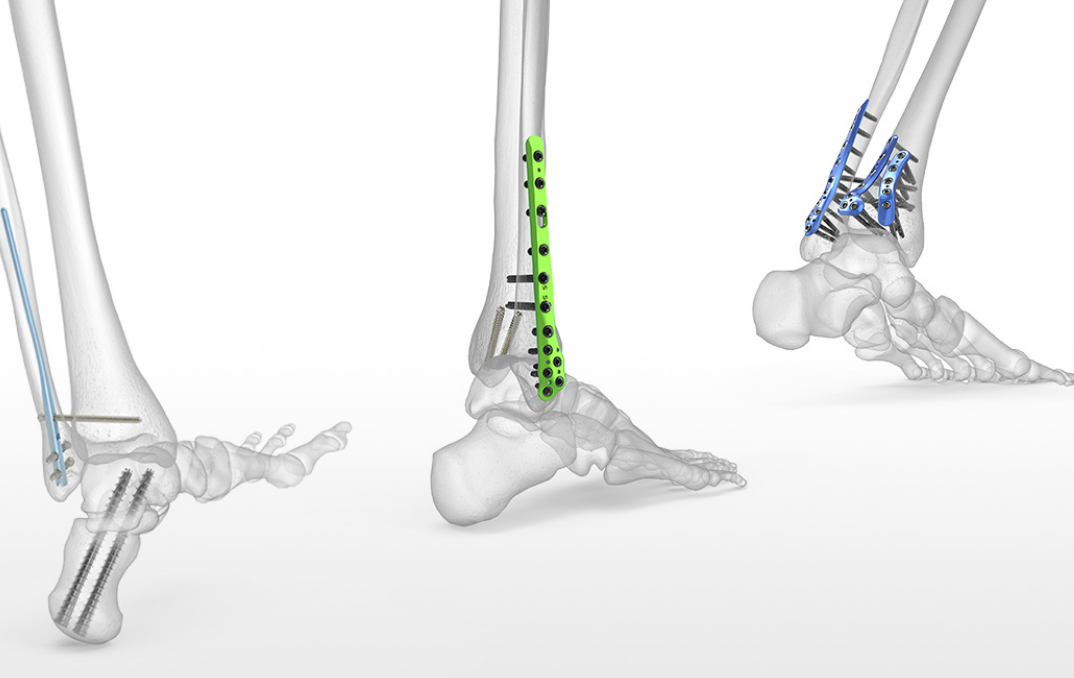

What Are The Best Types of Orthopedic Plates, And What Are Their Applications?

The main application of orthopedic plates and screws is fixation. But what is fixation? Bone fracture fixation is a technique that uses plates to stabilize the fractured bone, allowing it to heal faster and return to early mobility and full function more quickly. In this method, both sides of the bone are fixed with screws to stabilize the fracture and heal it in proper form. If you want to choose the best and practical fracture plate, you should consider these features:

1. The plate’s thickness and width should be proportional to the broken bone;

2. Neutralize all forces on fractures, such as bending, compression, shear, and torsional forces;

3. Hold both sides of the fracture symmetrically and with sufficient pressure;

4. It should be closed into the contour of the bone;

Medical bone plate is a medical device used for fracture treatment and bone reconstruction surgery, and its processing process requires several steps:

1. Designing and making the mold: First, the shape and size of the medical bone plate is designed based on the CT data of the patient’s bones provided by the doctor. Then, the corresponding mold is made.

2. Material preparation: The materials used for medical bone plates are usually stainless steel, titanium alloy, polylactic acid and other biological materials. Before processing, the materials need to be cleaned and disinfected.

3, Processing: The material is put into the mold, and through pressure and temperature and other conditions, the material is plastically deformed into the shape of the medical bone plate. Commonly used processing methods are forging, stretching, extrusion, injection molding, etc.

4. Surface treatment: The surface of medical bone plate needs to be polished, sandblasted, anodized and other treatments to improve its surface finish and corrosion resistance.

5. Inspection: After the processing is completed, the medical bone plate needs to be inspected for appearance quality, dimensional accuracy, mechanical properties and other aspects to ensure that it meets the strict medical device standards.

The production of medical bone plates requires certain qualifications and technical conditions. In China, a medical device manufacturing license is required to produce medical bone plates, such as ISO 13485 quality management system certification, etc.

As an important medical device, the production of medical bone plates requires strict production management and quality control. As an important medical device, the production of medical bone plates requires strict production management and quality control. Only companies with the right qualifications and technical conditions are able to produce medical bone plates that meet the standards and make a positive contribution to the medical industry.

As a company that can produce medical bone plates, we will fully comply with the relevant national regulations and standards, establish a strict quality management system, and introduce advanced production equipment and technology to ensure the quality and safety of our products. At the same time, we will actively carry out technological innovation and research and development to promote the development and progress of the medical bone plate industry.

If you are interested in medical bone plates and other related medical devices, please contact our engineers at [email protected] We can customize specialized apparatus for you to ensure any purpose you need.