Features of 5-axis machining center

The characteristics of the five-axis machining center machine tool should be compared with the traditional three-axis equipment. Three-axis processing equipment is relatively common in production, and there are several forms such as vertical, horizontal and gantry. Common processing methods include end mill end cutting and side cutting. The profiling of ball nose knives, etc. However, no matter which form and method have a common feature, that is, the direction of the tool axis remains unchanged during the machining process, and the machine tool can only realize the Cartesian coordinates of the tool in space through the interpolation of the three linear axes of X, Y, and Z. movement in the system. Therefore, in the face of the following products, the disadvantages of low efficiency of three-axis machine tools, poor surface quality and even inability to process are exposed.

Compared with the three-axis CNC machining equipment, the 5-axis machining machine has the following advantages:

1. Maintain the best cutting state of the tool and improve the cutting conditions

2. Effectively avoid tool interference

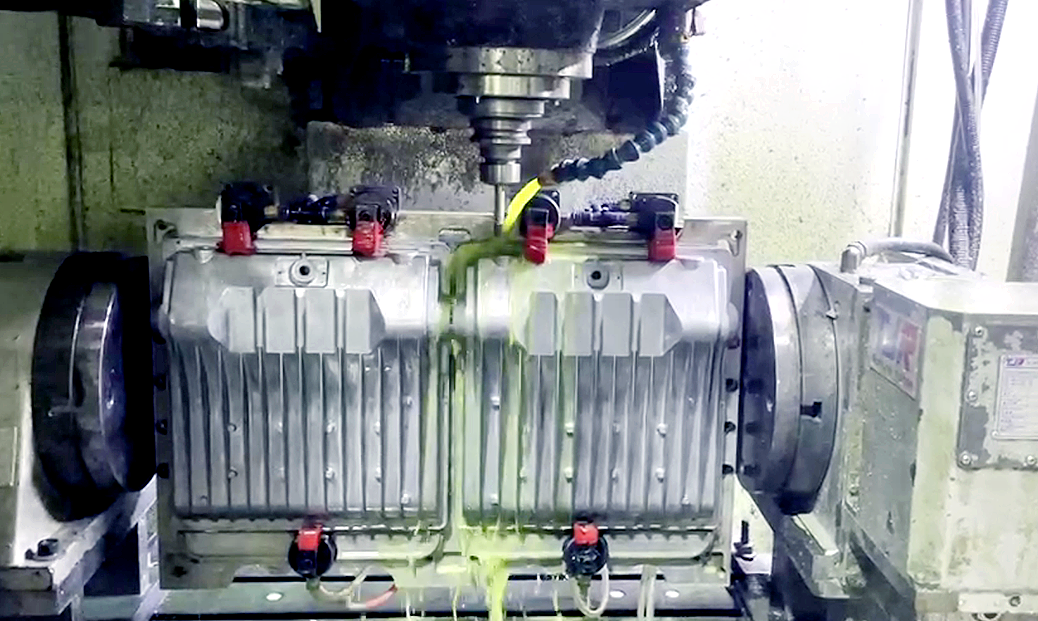

3. Reduce the number of clamping, and complete five-sided processing in one clamping

4. Improve processing quality and efficiency

5. Shorten the production process chain and simplify production management

6. Shorten the development cycle of new products