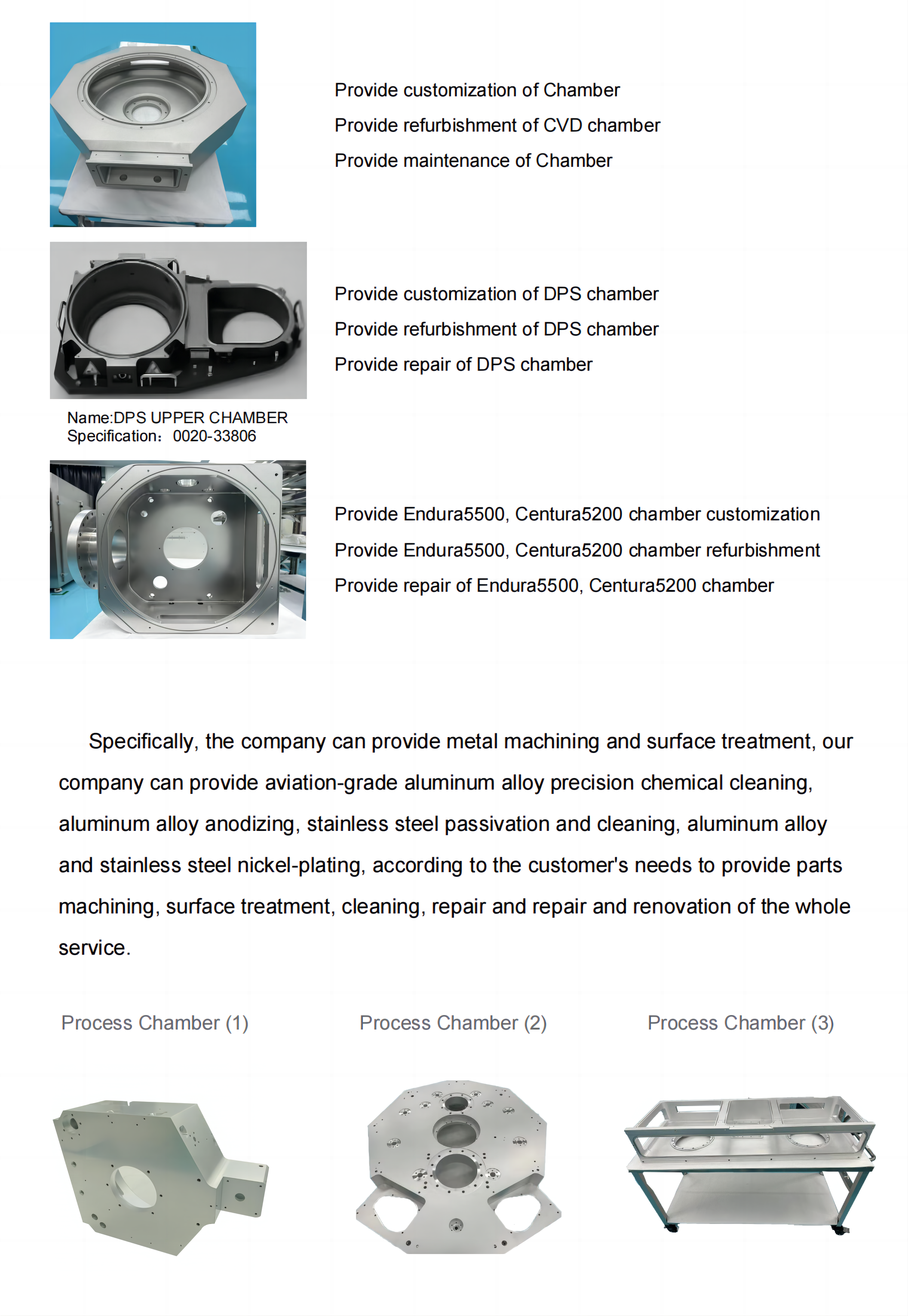

vacuum chamber

OTHER configuration:

- Chamber Materials:

- Stainless steel is preferred for its corrosion resistance.

- Size:

- Larger chambers may be required for bigger substrates or multi-chamber systems.

- Pumping Speed:

- Align speed with outgassing rates; consider turbo or oil-free pumps as needed.

- Ultimate Pressure:

- Precision processes require low residual gas levels.

- Process Gas Compatibility:

- Ensure materials are compatible with process gases to avoid adverse reactions.

Product Description

product size chart or static pressure:

Product Specfications

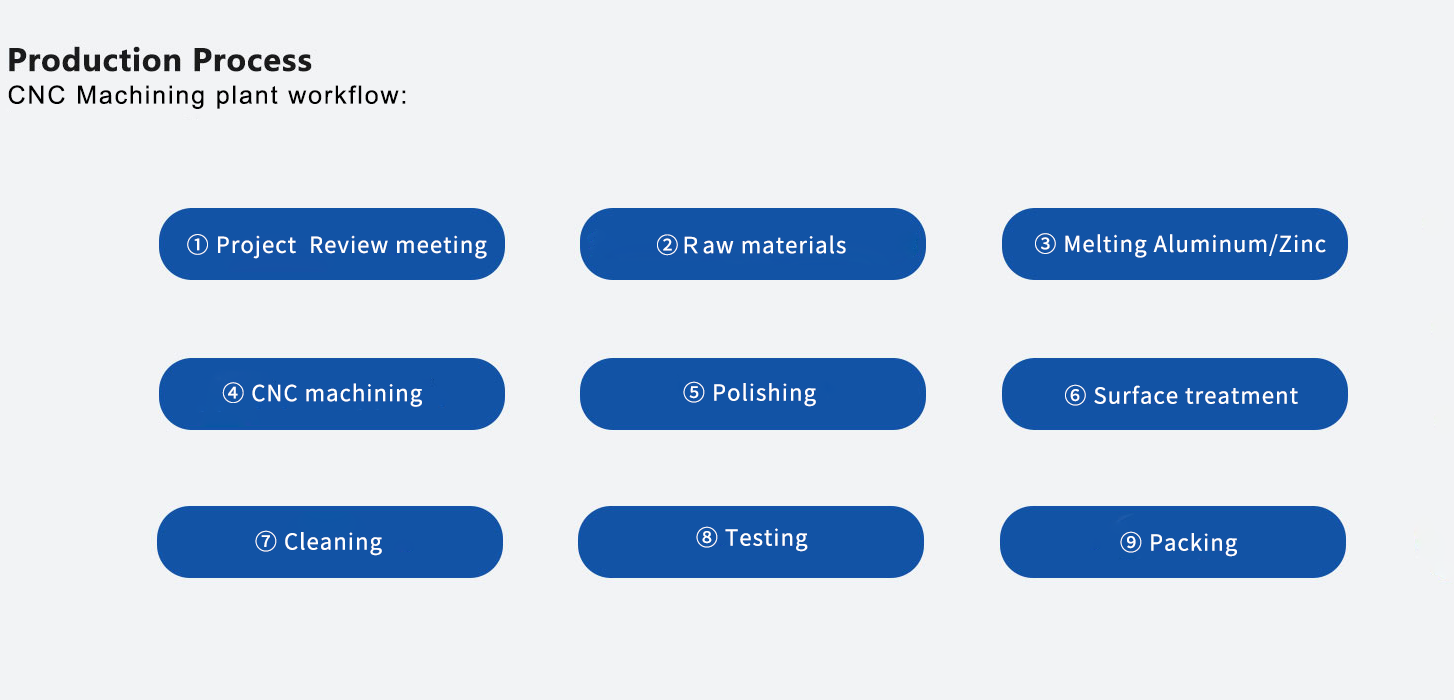

XY-GLOBAL provides customers with high-precision metal parts processing, to meet customer parts cleaning and surface treatment requirements, to achieve the whole process from machining to surface treatment, for the major semiconductor, photovoltaic manufacturers of services,

The company can provide metal processing and surface treatment, our company can provide aviation-grade aluminum alloy chemical cleaning, aluminum alloy anodic oxidation, passivation and cleaning of stainless steel, aluminum alloys and stainless steel nickel-plating, according to the customer’s demand for professional surface treatment and cleaning for semiconductors and photovoltaic and LED manufacturers to provide parts processing, surface treatment, cleaning, repair and repair renovation of the whole service.